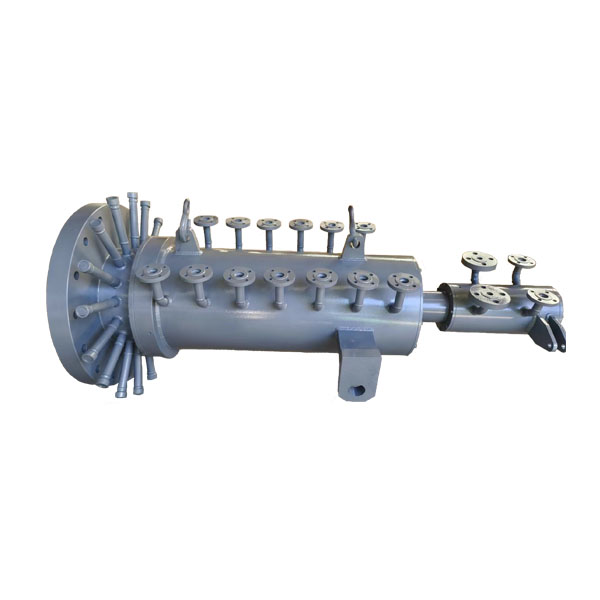

Two-way flow-through type HMS

Structural characteristics

HM series rotary joints are designed according to the modern steel continuous casting equipment, it also applies to other industries, especially in the case of limited external installation dimensions, its main feature is that most of the joints are deep into the rolls, and only the pipeline connecting elbow is exposed on the outside, which is conducive to the assembly arrangement of the external space, and it is more aesthetically pleasing. In addition to adopting smooth design, the sealing structure also changes the original axial tandem type into inverted built-in type, which not only reduces the axial length, but also integrates the flange and shell, which is more favorable for disassembling, assembling and maintenance of the joints.

One-way flow-through type HMD

| norm | A | Mounting hole D(H8) | Mounting hole L | d | D1 | L1 | L2 | E | F | G | H |

| 15 | Rc1/2 | 46 | 62 | 16 | 59 | 64 | 60 | 46 | 20 | 4 | 45 |

| 20 | Rc3/4 | 46 | 62 | 17.5 | 59 | 64 | 60 | 46 | 20 | 4 | 45 |

| 20 | Rc1 | 46 | 62 | 17.5 | 59 | 64 | 60 | 51 | 20 | 4 | 60 |

| 20 | Rc1 | 59 | 82 | 25 | 73 | 73 | 76 | 52 | 21 | 4 | 60 |

Two-way flow-through type HMS

| norm | A | B | C | d | Mounting hole D(H8) | Mounting hole L | D1 | L1 | L2 | L3 | E | F | G | H |

| 15 | Rc1/2 | 51 | 85 | 14 | 46 | 62 | 59 | 71 | 60 | 49 | 47 | 20 | 4 | 39 |

| 20 | Rc3/4 | 51 | 85 | 14 | 46 | 62 | 59 | 71 | 60 | 49 | 47 | 20 | 4 | 39 |

| 20 | Rc3/4 | 51 | 85 | 19 | 59 | 82 | 73 | 72 | 76 | 63 | 48 | 21 | 5 | 39 |

| 25 | Rc1 | 64 | 105 | 28 | 71 | 94 | 86 | 95 | 82 | 80 | 65 | 23 | 5 | 43 |